Part 1

- Designing an aircraft

is a major task. World wide in big companies employs 100s of engineers to

design aircraft and its components. Nevertheless with so many years in

aircraft designing, the industry has a road map of how to go about

designing an aircraft.

2. A typical design of aircraft goes through following steps :-

-Studying user requirements

-Literature and historical

survey of available aircrafts of the class and available technology

-Feasibility and

constraints

-Preliminary Design

-Weight calculations

-Drag Polar Calculations

-Weight estimations

-Selection of optimum wing

loading

-CG Calculations

-AC Stability Calculations

- Let us take a small

exercise of designing a 40, 000 Kg Freighter which can take upto around

400 passengers. Its range should be around 6500 – 7000 Km and endurance to

be about 8 hrs. Mach no to be at 0.8 – 0.8.

- A Survey of following

aircrafts was undertaken.

-

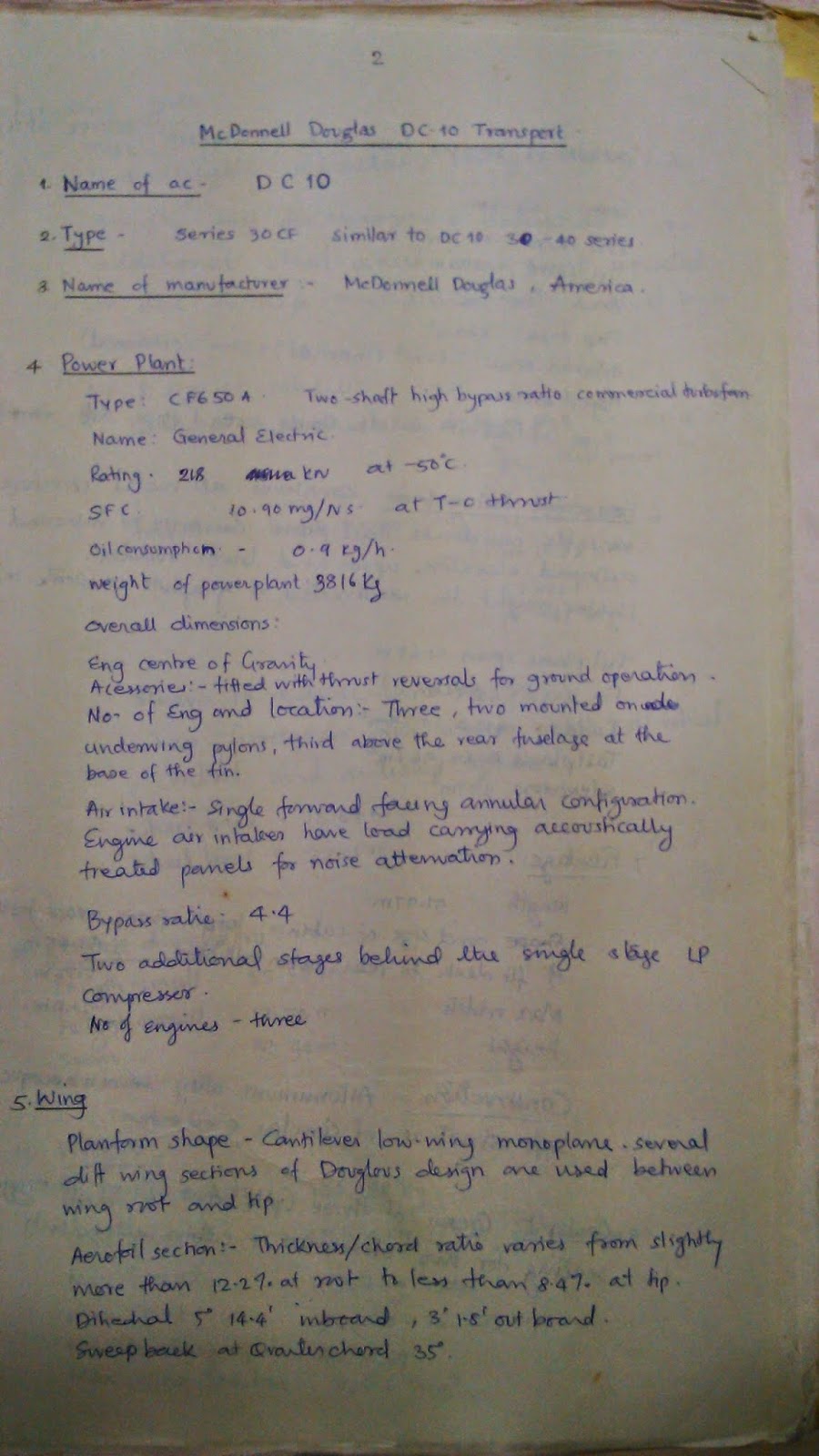

Mc

Donnell Douglas DC – 10 Transport.

-

Aribus

A 320.

-

Ilyushin

76.

-

Lockheed

L- 100 Series.

-

Ilyushin

86II.

-

Boeing

707.

- As an example the

survey of Mc Donnell DC 10 is given here, then when all the aircrafts of

the same class were studied, ‘Ratios were obtained from the collected

data’ so that general indications of fuel weight, basic empty weight, wing

loading, powerplant could be arrived at.

The ratios of various parameters such

as fuel weight, basic empty weight, wing loading, power plant is given here.

RATIOS OBTAINED FROM

COLLECTED DATA